Car and Car Conversions

A slightly shortened version of the Car Clinic from Performance Car, Feb' 1994.

CCC' Clinic is nothing if not eclectic. This Month, one of the Finest examples of Britain's thriving specialist car industry, the Ginetta G33,comes under the steely gaze of Gerard Sauer and Dave Walker

Love them or not, some cars are special, deserve respect and cannot be ignored. Such is the case with the subject to this months in-depth investigation the Ginetta G33, one of the latest in a long line of low volume sports and racing cars originally designed and built by the Walklett brothers.

The Ginetta model range has included sports racing cars, formula Fords and two seater coupes as well as open top roadsters such as the G33. All of them where built following the construction methods favoured by many of their contemporaries. During the early Ginetta days – the Walklett era, if you like – Lotus was probably the leading manufacturer in this category. Like many other specialist car builders, Ginetta strove to emulate the Lotus philosophy of light weight and agility.

Ginetta's have used various engine combinations over the years, including the BMC 1500 pre Cross flow Ford, BMC A series and perhaps the most famously the Chrysler Imp units in 875 and 998cc capacity. Later on the ubiquitous Ford Cross flow was used in the G33 and in that guise the marque was very successful in club racing at national level.

Many Ginetta customers purchased the cars in the most basic form, and then began modifying them extensively for racing purposes. Eventually though ever more restrictive legalisation, the demands of a more discerning customer base, and rapidly escalating costs of developing new models, caused profit margins to disappear.

As was the case with many other similar small volume production cars manufactures, albeit somewhat later than many others, Ginetta finally faced extinction. Then along came its present owner, one Martin Phaff, a car enthusiast and entrepreneur who put his money where his mouth is and became owner and managing director of Ginetta cars. After weathering a financial crisis in 1992 the company came through leaner and fitter and looking forward with confidence to a healthy future, a thorough review of the model range was conducted, with the result that the dropped G33 was reinstated and updated to reflect the demands of the eighties.

Like a number of other kit car manufactures, Ginetta discovered the successful formula that gives a lot of performance for a modest outlay: the big V8 in a lightweight chassis. Cars like the Westfield Seight, TVR Tuscan, Morgan Plus Eight and Marcos Mantula have successfully proven that customers are prepared to pay for that performance package. Our particular example of the G33 and subject to this months clinic belongs to Mick Stubbs, and is chassis number 24 and is reputed to be the one of the 1991 London Motor show cars.

The G33 is powered by the fuel injected 3.9 ltr V8 and the power is fed from the flywheel clutch assembly into the Rover SD1 5 speed all alloy gearbox. A short one piece prop shaft feeds the torque into an all alloy differential from the Ford Sierra range which has a 3.14:1 final drive ratio. Its mainly the gearbox that lets the car down as the ratio spacing is awful with big (too big) gaps between seconds and third as well as fourth and fifth. Its jus as well that the engine has a good torque spread, otherwise a change in final drive ratios would be considered compulsory.

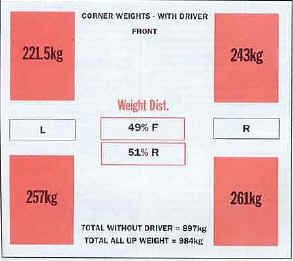

As you can see from the figures the weight distribution of the car is very good. With the driver behind the wheel the slight front bias almost disappears and so there is almost perfect 50/50 weight distribution. When Dave did the corner weights there was a fair bit of adjustment necessary to get the car to sit square, and this made a great deal of difference to the subsequent behavior of the car. With the 9 gallon (a bit small on this type of car) mounted low in the frame and the overall height being only 1.041 m the center of gravity is obviously very low. With a 1.382m front track width and a rear track of 1.387 m there is no need for hefty roll bars or overly heavy springs.

Often with highly specialized cars, it's easier to get detailed information about their specification because manufacturers are much more open and enthusiastic about the product they are selling. We contacted the factory as a result of doing our work at the Clinic and they told me there had been a change in specifications mainly concentrated in the suspension. The early cars had 300lb springs on the front and 225 at the rear, which was then change to 325lbs on the front and 200lbs on the rear. This rapid reaction and upgrades can sometimes lead to confusion, but in the main it tends to benefit the customer greatly since the ongoing work with the cars means upgrading in parallel with the factory is always possible. There is not a single car in the world that once sold cannot be improved.

With an overall length of 3.632m and a wheelbase of 2.235m the car can fairly be described as having a short wheelbase. As a gauge the Honda NSX, acknowledged as the standard in sports car handling and ride has a 2.53m wheelbase. It is certainly interesting to see such a short wheelbase on this car since the G21 (one of the most beautiful looking coupes around) built in the early seventies had a 2.31m wheelbase.

When talking to the factory we discovered that the MK2 version is going to have its wheelbase extended by 7cm. Although this does not sound like much, we are convinced that this will be a very worthwhile improvement. Being such a low car it is inherently a flat handling vehicle, and the only criticism of the car we found in the handling department was a slightly floaty feeling at high speed (75-80 mph).

We are also pleasantly surprised to lean that the factory do take account of the type of work that the car will be used for and will adjust the chassis settings to suit. Our car appears to be a road setup. With front castor being set at between 3 to 4 degrees, and camber to about 1 degree negative, the car would benefit greatly from an increase in both. At the front the suspension consists of unequal length double wishbones arrangement and a coil over shock absorber arrangement with adjustable spring platforms. The shock absorbers are gas filled Spax and they have 12 stop adjustment at their base. At the rear is again unequal length wishbones, but the lower ones are triangulated. Shock absorbers are the same coil over type with 12 stop adjustment, although they are a different rate. At the front the shocks are believed to be 120/210 bump /rebound rate, whilst the rear are 100 /185 bump to rebound. The roll bar at the front is a relatively small diameter 16mm. In every other respect the suspension arrangement both front and rear are of light weight and designed to minimize camber change during roll.

Wheels and Tyres

The wheels are made by Fondmetal of Italy and of 7 x 15 both front and rear, with a ford 4 bolt fixing. These wheels are very good looking, but they do have a fair bit of offset and this is reflected by the amount of kickback through the steering wheel. Tyres are Goodyear eagles and they are ZR rated, measuring 245/50 x 15, set to 20 psi cold. At the time of our Clinic, the profile depth of tread was 8mm, and as this is close to the new depth tyre wear should be good.

When talking to the factory about Mick's car they told us there had been a G33 racing series in Sweden, not dissimilar to the Cateram series here, and to prove the point about racing improving the breed, the factory have leaned a lot from that. All this knowledge has been put to good use in the new MK2 version. The proposed changes are briefly: 7cm longer wheelbase, external fuel filler, softer bonnet bulge, square cornered windscreen; revised hood (phew!), integral headlights, improved dashboard; lower roll centers front and rear, new five spoke alloys with reduced offset; increased steering castor; and increased wishbone arm length front and rear.

There are several interesting aspects of these changes, which are most interesting. The lower roll centers both front and rear should help by giving the driver better feedback. The lengthening of the wishbones, together with the reduction of wheel offset should reduce the steering kick back considerably. All this should translate into a better feel and a more stable car. Its quite possible that some of these changes could be retro fitted to earlier models except the roll center changes. The chassis has to be modified for that to relocate the pick up points, which would not be impossible on an existing chassis, just very difficult.

Brakes

The brakes have an easy time of it, the car being so light. The brake system used Cosworth 2wd disks and calipers with the disks turned down in diameter to 272 mm. The rear disks are from a Sierra XR4 x 4 and include the handbrake mechanism. Master cylinders are twin Girling separate cylinders of 0.70 “ diameter with a balance bar. The system does not need a servo, and the pedal ratio is set at 6:1 and gives good feel at reasonable pressures. It is almost impossible to lock up the wheels and only very insensitive use will provoke this. Several runs on the high speed bowl slowing from 120 mph the car felt very secure under braking. Subsequent inspections of the disks showed they had not been stressed by this sort of repeated application.

Chassis

The chassis is a square section tube ladder type design, and appears to be very strong. However there is a fair amount of shake over rough roads. This may be in part due to how the body is attached to the chassis, as some manufactures see an opportunity to use the body to stiffen the chassis. Often this is only partly successful. On the rear there is a fabricated box section arrangement to take the differential and pick up points for the suspension. It appears to be inherently sound in design; of course the only way of really knowing is to do a twist test on the frame and measure the load needed to twist the chassis by 1 degree.

It would be interesting to know this figure for our Clinic car, but only a manufacturer or specialist race preparation shop could do this sort of thing. On the whole the car behaves consistently throughout all but the most extreme driving conditions. Due to a shortage of time however we where unable to test the car up to its limits.

Track Driving and Road Driving

From the moment you get moving with this car you cannot escape two immediate impressions. One is that the car is very long-legged, and two is that the car is somehow holding back. Its true potential is lurking there somewhere but is afraid to come out. We soon discovered that the reason for the strangulated feeling was the car was running far to lean. Dave has dealt with that as usual in the engine review section. The long legged feeling is down to the low 3.14:1 final drive ratio and in truth this would probably benefit from the 3.62:1 ratio that can be fitted to this housing. The benefit would be both in better mid range response and reduce the effects of the awful gap between gears.

Feedback through the controls is good with the exception of the floaty feeling at high speed. Ultimate grip is very high indeed and the car never felt as if it was near the limit at any time. Handling too is predicable with sharp precise turn in being one of the features. Because we never did get the car near its limit its difficult to judge the car at this point. It is an important part of the tests however as if often reveals behavior traits that give clues to which part of the car that can most profitability be improved first..

Engine Diagnosis

Im not really a V8 man myself, but all the big V8 men I have come across tell me the same thing: V8 engines are all about torque, not BHP. Tress stump pulling, climb the side of a house torque ought to make Ginetta pretty exciting…so why wasn’t the owner that excited? Mick freely admits that the car was a bit of a disappointment. The performance was good, but not as good as he thought it was going to be. Over 200 bhp in less than a 1000kg car should make for a real point and squirt device, even if it didn’t handle (See Mike Gerrards comments on the later MK2 spec).

As usual Gerard was busy playing at the track when there was work to be done, so it was up to me to jack up the car and record the corner weights. Because it has easily adjustable platforms I could not resist making a few adjustments while we where about it. The left front was very light, as was the right rear, so one adjustment to lift the front left spring should in theory correct both problems at the same time. Out came the C spanner. Mick sat in the car and I cranked away at the spring platform. It needed lifting about ¼’’ to get things reasonably close: within a few kilos across the back and just 21kg light at the front. Much better than the 41kg plus bias I had started with.

By now we were a bit late for the rolling road. Down at Superior cars I was a bit worried that the exhaust would not clear the rollers, but a bit of jiggling had the car sitting neatly in line for our power checks. The engine is stock Range Rover 3.9 litre v8 with no modifications at all including the standard fuel injection system. The only departure is the fitting of a K & N type air filter. We hooked up a CO meter more as an after thought than anything else but being all stock there were not going to be any problems, or were there?

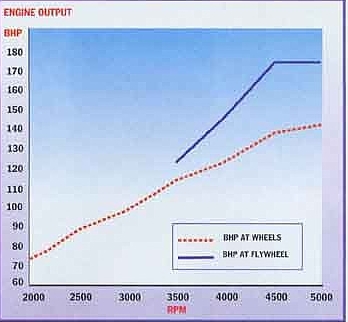

Starting at just 2000 rpm the engine took full throttle and recorded 76 bhp at the wheels in third gear. On engines that run this low Im more accustomed to seeing figures like 16BHP – on a good one obviously. The C0 was 2.6% which might be a touch weak, but Mick reports excellent fuel consumption, so perhaps this is how its supposed to run. By 3000rpm we had over 100 bhp at the wheels, but something was wrong with the CO meter with a reading of 0.6 % couldn’t be right surely? Perhaps the pipe had fallen out of the exhaust. It seemed OK so we pressed on. By 4000 rpm a reading of 126 BHP wasn’t looking too clever and when peak power of just 145 BHP at the wheels came up at 5000 rpm, and still under 1% CO – nobody was impressed.

The truth the mixture was dangerously weak through the rev range. The power we were seeing would not do justice to a reasonable rally spec Pinto. Let alone a 3.9 litre V8. Something was obviously amiss. Measuring the transmission losses confirmed that we had 173 BHP at the flywheel. We needed to get some extra fuel into the engine to confirm that it was the engine, not the meter playing up, although the lack of power was something of a clue in this direction.

As a bit of a bodge we hooked up a brake hose clamp to the return pipe for the injection rail. Letting the engine idle we adjusted the clamp until the reading was just under 4%. A check at 3500 rpm showed that we had gained 11 BHP, with a reading at 4.9% - much more like it. At 4500 rpm we now had a whopping 160 BHP at the wheels! Yet the CO was only 2.6%. We played with the clamp again and tried 5000 rpm, recording another 160 BHP. What we had proved was the car was seriously under-fuelled and it has massive potential which should make it a lot more exciting to drive.

Recommendations

My first recommendation is to get some fuel into the engine somehow. Probably an adjustable fuel regulator would be a good starting point. It seems obvious that the standard fuel map just isn’t doing the business in the Ginetta engine bay. An adjustable ECU would probably produce a lot more mid range torque, especially if you could play with the ignition as well as the fuelling.

It should be possible to dial the 200 BHP that the engine is supposed to come with. Once Mick got bored with that I would do a pair of heads for the car and put in fast road cam. Nothing too silly, just a 280’ degree duration hydraulic fast road job. The car is so light that you can afford to loose a touch of torque at 2000 rpm or so, to make the thing into the monster above 3000 rpm it should be….

Engineers Report

- Remedy lean running engine to avoid detonation damage or overheating. Investigate fitting balance pipe to exhaust. Increase fuel pressure and if not enough re-map ECU to suit. Set up car on rolling road.

- Fit harder springs on the front, softer on the rear as per factory evolution spec'.

- Fit uprated anti-roll bar, 25% harder.

- Increase front camber to 1.5 - 1.75 degrees negative.

- Try out 3.62: final drive ratio differential.

- Fair in nose opening to radiator with alloy sheet to give better cooling an improve aerodynamics.

- Change exhaust flanges for thicker material spec' to avoid leakage.